All You Need to Know About Water Soluble Purging Paper and Tape

In this article, we would like to discuss water-soluble purging paper and tape, or what is also known as dissolvable paper and tape. When it comes to these items, there are several things that you should know about them. Here are some of the things that you need to know about water-soluble purging paper and tape:

In a Nutshell

First of all, you need to know what they are. If you are wondering what water-soluble purging paper and tape are, then we will explain it to you in a nutshell so that it is easier to understand.

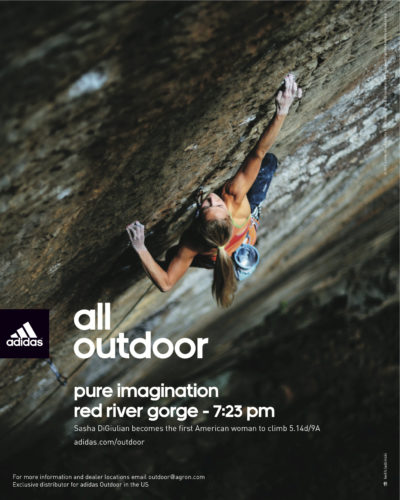

When it comes to traditional purge systems, we can say that there are notable limitations such as costs, labor intensiveness, and inefficiency. So that we can overcome those limitations, the dissolvable paper and tape can be used to construct unique purge dams that are better than the traditional ones.

Benefits and Advantages

Wooden pulp and sodium carboxyl methyl cellulose comprise these water-soluble paper, which enables them to dissolve completely and quickly in most liquids. It provides a wonderful barrier to retain argon, helium, and other noble gases that are within the weld zone of a TIG welding of aluminum pipes and stainless steel.

With their abilities to be near the weld zone, it can increase the efficiency of the whole process of welding. It also eliminates unnecessary costs and inconvenience to the welding process.

Other than that, there are also ones that have a biodegradable composition, which doesn’t leave any residues in the pipeline. They are also available in a vast selection of sizes and grades, which permits purge dam constructions for any pipes with any diameters.

Plus, they are very easy to store, easy to remove, and easy to use. They are also ideal for a wide array of industries, like the petrochemical, nuclear, as well as the food and beverage industries.

How It Works

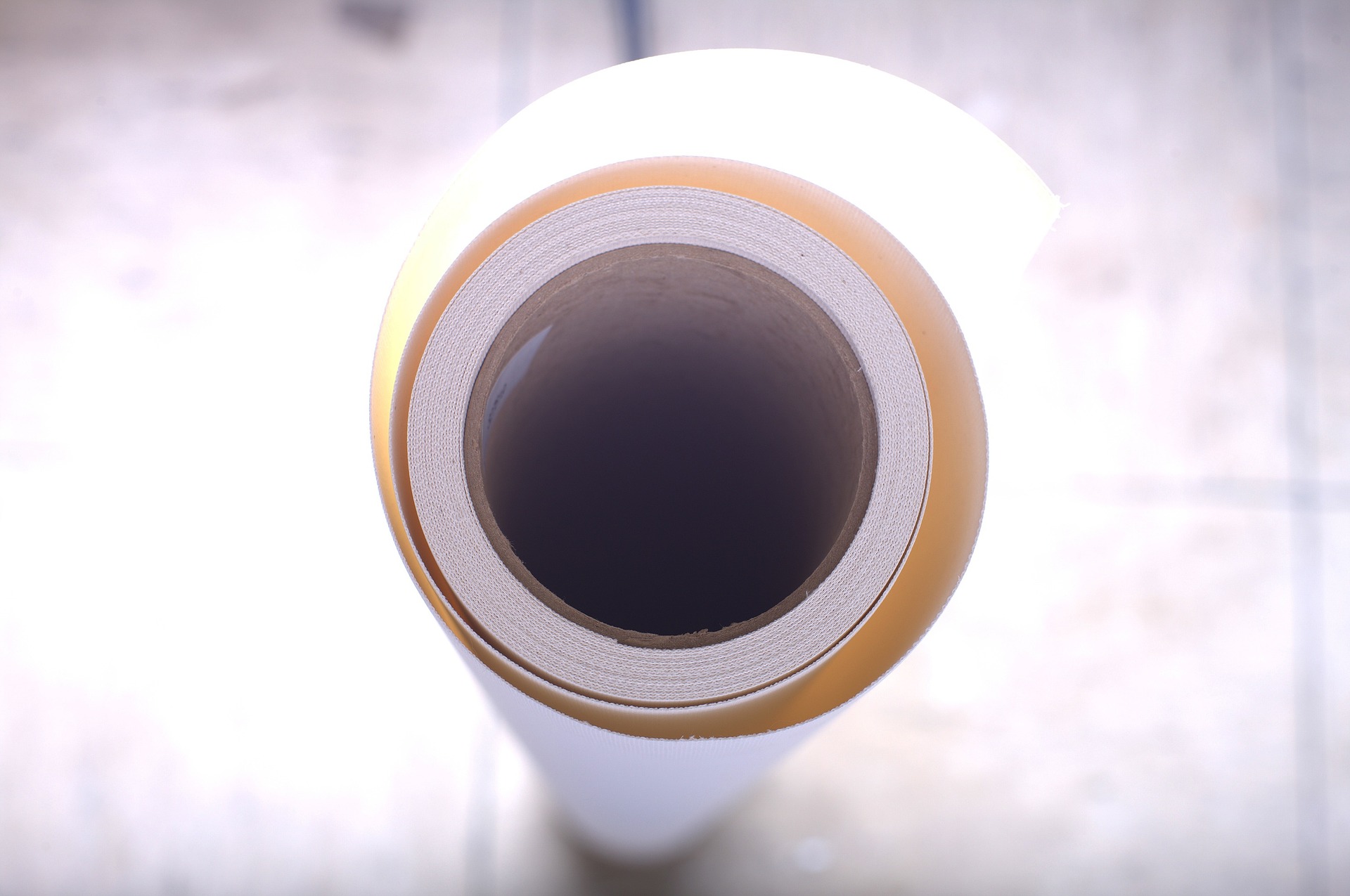

The first thing you need to do to use them is to trace the inner diameter of your pipe by pressing the paper along the edge of the pipe to create an impression. After that, fold it to form a ninety-degree angle. Then, you cut around the impression in a circle of about one-third times bigger than the diameter of the pipe.

After cutting, slit it into one to two-inch segments that are perpendicular to the impression, creating the first slit at the twelve o’clock position. Then, followed by the three o’clock position, six o’clock, and so on. After that, position it inside of the pipe and tape it in place to secure it.

To activate the dissolvable tape, first, moisten a sponge. Then, lightly dab it along the tape. After that, introduce noble gas by inserting a purge gas needle into the root gap whilst ensuring the connection to the gas line. When that is done, carry out the process of welding. After welding is done, perform a hydro-test to introduce water so that the paper and tape dissolve.…

Today, there is more focus on cordless tools. They are more useful than the corded ones. However, each has their pros and cons, and the buyer will be the final decision maker depending on what they want. Some argue that cordless power tools do not have consistent power, especially those involved in tough jobs like drilling holes on metal surfaces.

Today, there is more focus on cordless tools. They are more useful than the corded ones. However, each has their pros and cons, and the buyer will be the final decision maker depending on what they want. Some argue that cordless power tools do not have consistent power, especially those involved in tough jobs like drilling holes on metal surfaces. As people become more innovative, they devise tools with extra features for safety and making work easier. When buying a power tool, it is ideal to check this. Keep in mind that the more features they have, the better it will serve you.

As people become more innovative, they devise tools with extra features for safety and making work easier. When buying a power tool, it is ideal to check this. Keep in mind that the more features they have, the better it will serve you.